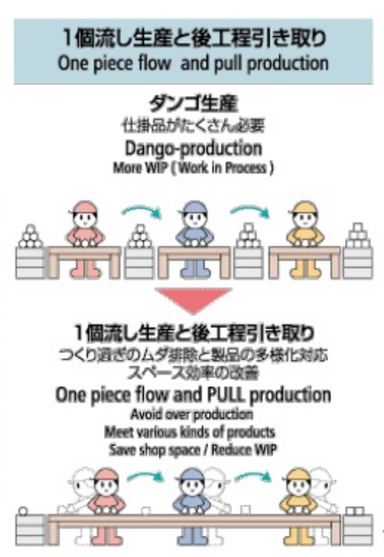

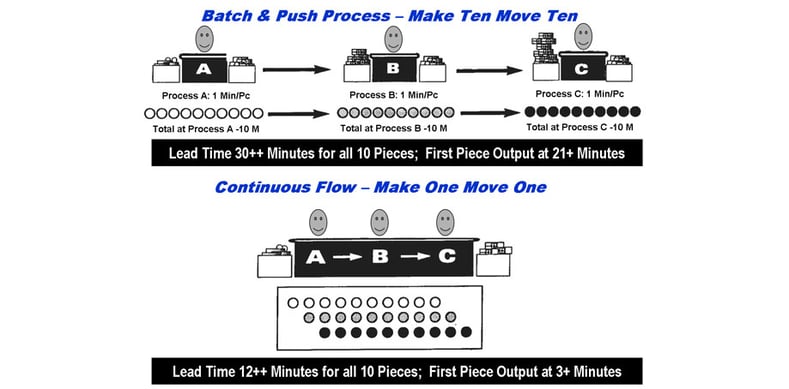

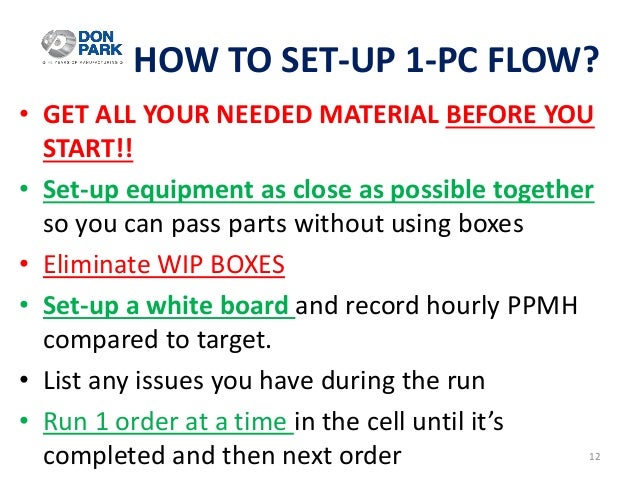

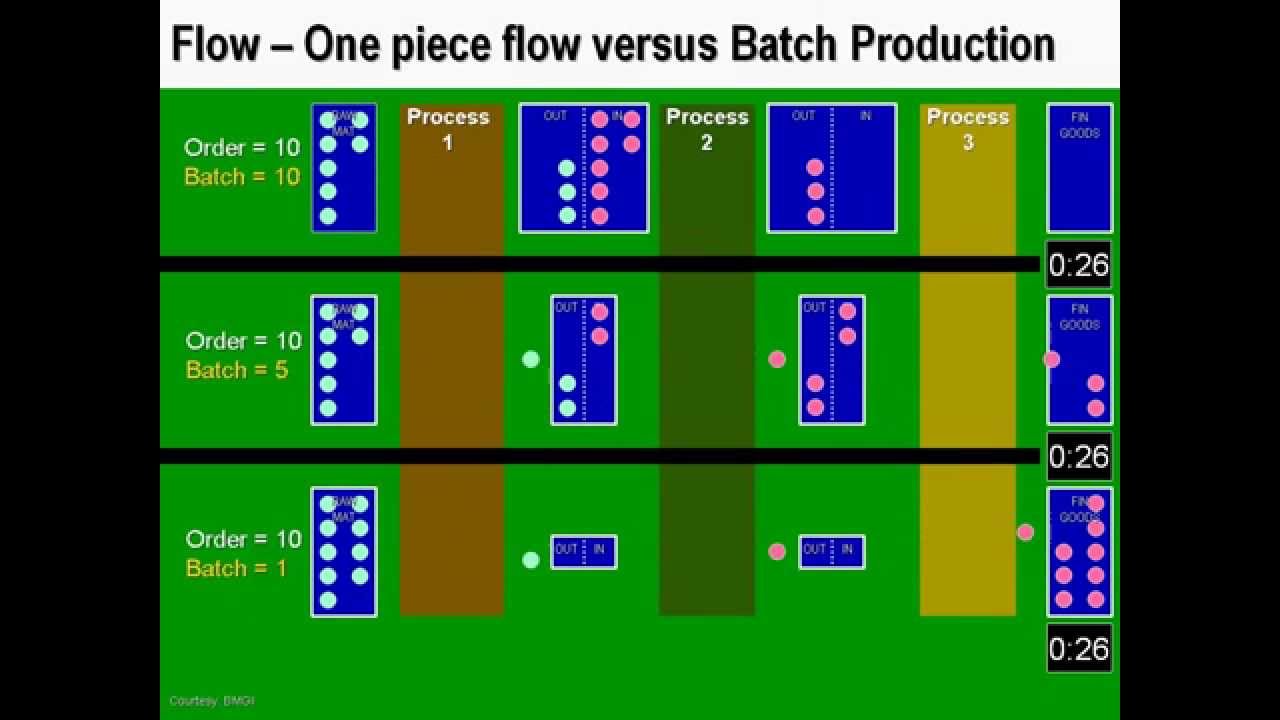

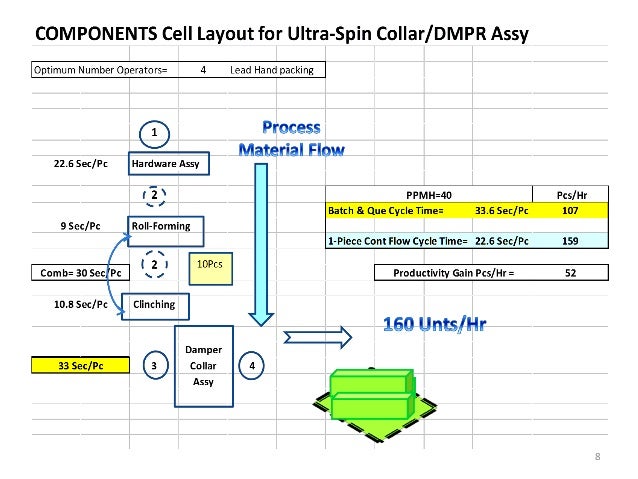

•Crew size calculation for an assembly line doing one piece flow paced to Takt Time isCrew size = Sum of Manual Cycle Time / Takt Time •If Manual Cycle Time = 1,293 seconds and a Takt time = 345 sec •Crew size = 1,293 personseconds / 345 seconds •Crew size = 374 people •In this case the crew size will be 4 people since 3 people Onepiece flow means that parts are moved through operations from step to step with no workinprocess (WIP) in between either one piece at a time or a small batch at a timeSingle Piece Flow, Continuous Flow & Standardized Work – Workers are closely coupled Can help each other – Information is current Action is quick and focused • Man Multi‐skilled workers can perform multiple processes, thus offering great flexibility • The most effective way to work at particular operation, given safety

2

One piece flow vs batching pdf

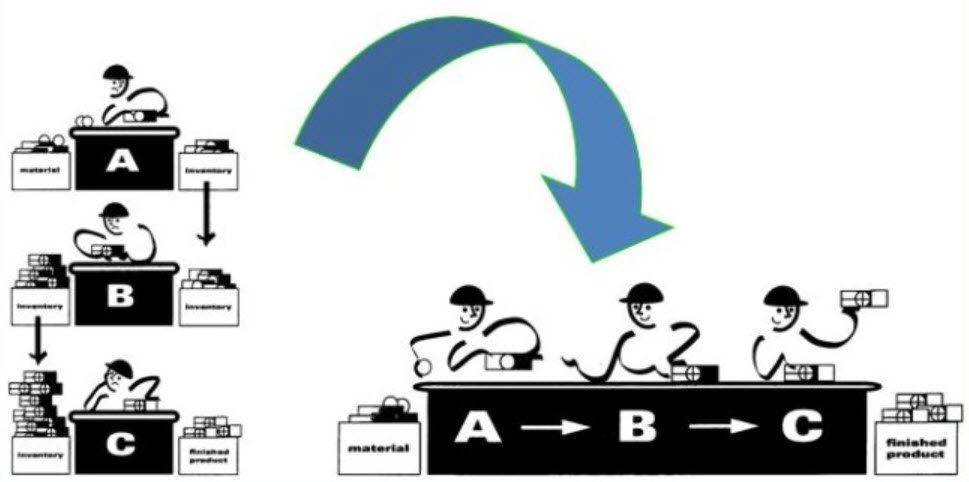

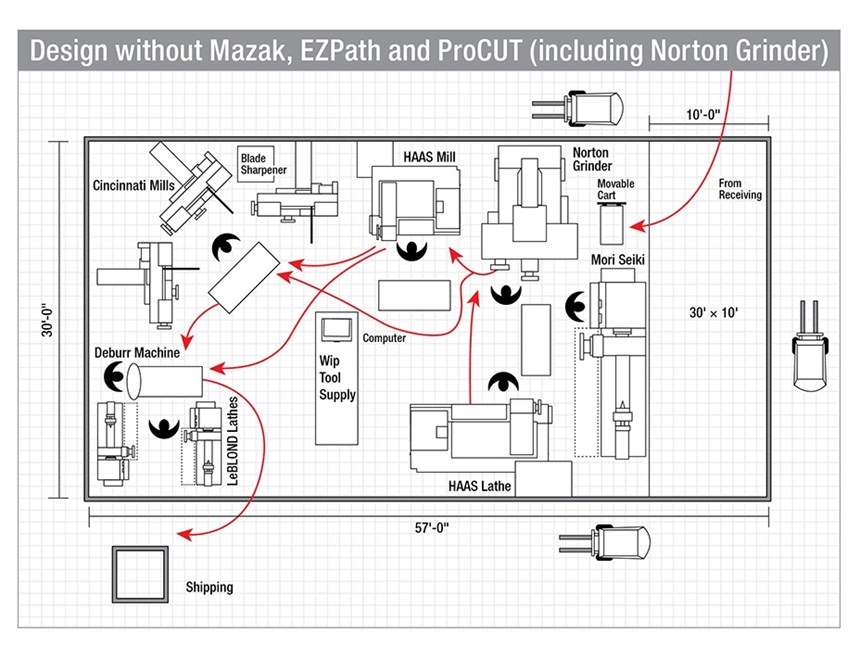

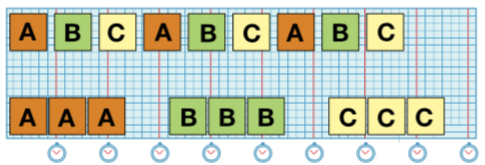

One piece flow vs batching pdf-Referred to as one piece flow or make one, move one The opposite of continuous flow is mass or batch and queue production where material is pushed from one process to another no matter if the material is needed downstream or not In order to make value flow one piece at a time we must 1 Become the "thing" in question 2In the simplest of terms, onepiece flow means that parts are moved through operations from step to step with no workinprocess in between either one piece at a time or a small batch at a time This system works best in combination with a cellular layout in which all necessary equipment is located within a cell in the sequence in which it is used

Continuous

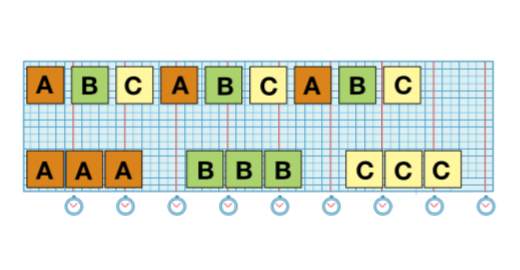

One piece flow means production of the product moves from one stage to the next stage one piece at a time Compare that to lot production where several units are made at a given stage and then all are moved to the next stage at the same time Most operational excellence practitioners promote one piece movement Hi I like your article One thing I am interested in is how I can quantify the benefits so my business case is compelling I am thinking that I need to plot out our current batch process and establish a cost per function, ie batch WIP at each step, value for space (m2/$) per function, etc, then overlay a one piece flow process and use the difference to set the caseOnepiece flow, can you get twopiece or threepiece?

There are two main advantages of one piece flow;• Enable FIFO at the batch level • Reduce inventory levels throughout processes • Avoid overproduction • Increase visibility of bottlenecks in the process ONE PIECE FLOW • Enable FIFO to a single product / service level • Create transparency of the real process lead time • Reduce lead time • Reduce inventory levels throughout What is One Piece Flow?

Singlepiece flow would mean I would add every ingredient, one after the other, to the first salad bowl, and complete that salad (so it could flow), before working on the second salad, and so on This kind of setup would require me to leave all the ingredients out in the preparation space until the last salad was done OnePiece Flow is a lean manufacturing concept that is aimed to achieve a discrete flow of work contrary to 'batch' production approach In simple terms, it means onebyone processing of a product A single unit of product flows between different processes It follows the old adage 'One step at a time'Continually move closer to the ideal state Activity Batch Processing vs Continuous Flow Processing The human mind likes batches!

Ppt Brief Overview Of Batch Vs One Piece Flow Powerpoint Presentation Id

Batch V Lean 1 Piece Flow Training

Simply speaking, the goal of onepiece flow is to have a single item or unit of product flow from process to process with no delays or bottlenecks in between The continuous flow approach contrasts with batch production and mass manufacturing In batch production, units are moved from process to process as a batch→ One Piece Flow is moving one workpiece at a time between a work station within a cell or shop → In opposite conditions, we might process an entire batch or lot at each station before moving it to the next station → In simple language, it means that the parts are moved through operations from station to station with no workinprocess (WIP) atSinglepieceflow contrasts to traditional 'batchandqueue' production, which is the mass production practice of making large lots of a part and then sending the batch to wait in the queue before the next operation in the production process A 'push' production system is used, whereby a previous process manufactures as much as it can, without regard for the actual requirements of

Ten Reasons Why One Piece Flow Will Not Work Gemba Academy

One Piece Flow Vs Batch Experiment Beanietech

Decrease the average patient's length of stay This case study examines one piece of the complex patient flow process Historically, hospitals did not have to focus on market competition Now, they are lagging behind other industries in learning how to improve their processes (Pontifical Institute ofOnePiece FlowKenichi Sekine By reconfiguring your traditional assembly lines into production cells based on onepiece flow, you can drastically reduce your lead time, staffing requirements, and number of defects Kenichi Sekine studied under the late Shigeo Shingo and is responsible for many recent advances in theA great activity for demonstrating onepiece flow Lean Bucket Brigade Game Not so much a game as a video showing a method that could be used with different games Bears in Space A six sigma training game using gummy bears to create a Design of Experiments Kanban game with lego served in cups Simple game showing pull system technique Lean

2

One Piece Flow Manufacturing Creative Safety Supply

That your work is completed faster and that you save money both due to the time and space you free up That said, these simple benefits have huge knockon effects First up, using one piece flow can make your final results higher quality than if you tackled them in bulk This is because errors are more likely to be• BatchingSingle Piece Flow • PushPull • Standardized Work • Kanban • Brainstorming, Affinity Diagram, Impact Control Matrix • Clean Sheet Redesign Simpler, Faster, Better, Less Costly LeanOhiogov 34•BatchingSingle Piece Flow •PushPull •Standardized Work •Kanban •Brainstorming, Affinity Diagram, ImpactControl Matrix •Clean Sheet Redesign Simpler, Faster, Better, Less Costly LeanOhiogov 34

One Piece Flow Vs Batching A Guide To Understanding How Continuous F

Batch V Lean 1 Piece Flow Training

Improves Flexibility Level In addition to that, one piece flow improves the flexibility level in a great way because it is quicker as compared to batch and queue Due to the factors of the one piece flow being faster, it is possible to wait longer to plan the order and yet deliver in time Consequently, it allows us to comply with last minutes Certified Lean Six Sigma Master Black Belt Recommended Batch v Lean 1 piece flow training Julian Kalac PEng Standard Work And One Piece Flow guest399e73 One piece flow eigelsi One Piece Flow VS Mass ManufacturingOne touch (producción de un solo toque, a la primera, etc) QUE ES UN SISTEMA DE PRODUCCIÓN?

One Piece Flow Vs Batch One Piece Flow Vs Mass Production One Piece Flow Lean Manufacturing Youtube

Batch Vs One Piece Flow Manufacturing Treston

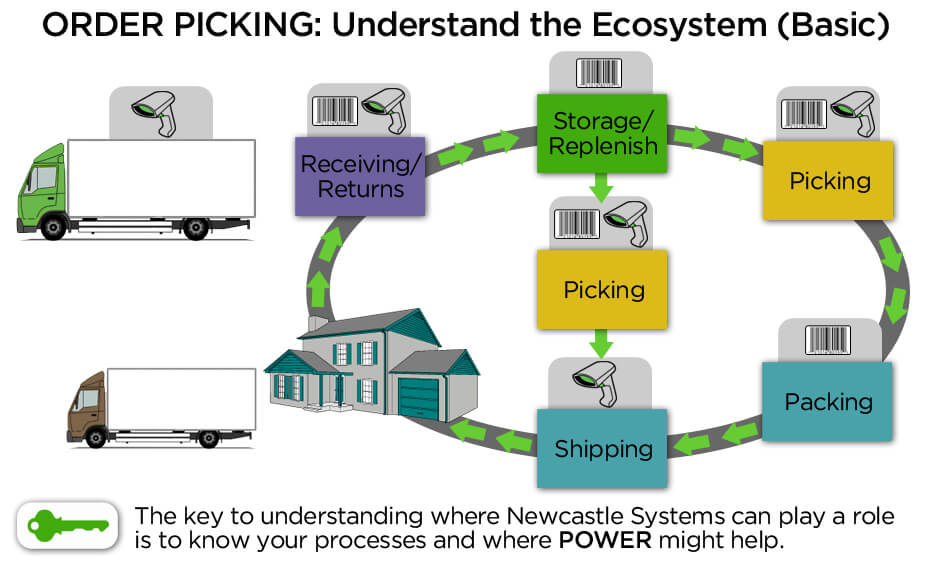

Much like the picking technologies, batch sortation can be performed utilizing paper, RF, voice, or a puttolight system (which is a reverse of a picktolight system) Since a piece pick batch sortation is typically in a condensed area, usually consisting of sections of carton flow rack or shelving, the methods that are mostChapter 3 – One Piece Flow The One Thing Make a batch and waste will be everywhere OR make one, make it right and waste will magically disappear Identify one area where you are currently doing batchwork Time how long it takes you to make 10 products as a batch Now, time yourself making one at a time until you reach 10 Lean FastCap StylePulverizer, Plastic Compounding Pulverizer Machine,Powder Making Machine One Piece Flow Vs Batch ONE PIECE FLOW Vs MASS PRODUCTION One piece flow lean manufacturing Batch Processing in 19 GMP Training by Example What Not to Do with Batch Records \u0026 CoA MistakesLtA Computing and Computers Batch

Batch And Queue Vs One Piece Flow Quarter Activity Continuous Improvement Blog

Glass Batch An Overview Sciencedirect Topics

41 One piece flow (flujo de una sola pieza);This video talks about the One piece flow sometimes referred to as "singlepiece flow" or "continuous flow," and how is it different from Batch productionBatchandQueue – the mass production practice of making large lots of a part and then sending the batch to wait in the queue before the next operation in the production process In health care we batchandqueue people Singlepieceflow – a situation where products (or people) proceed one complete product at a time through various operations

Batch V Lean 1 Piece Flow Training

Difference Between Batch Processing And Single Piece Flow Hash Management Services Llp

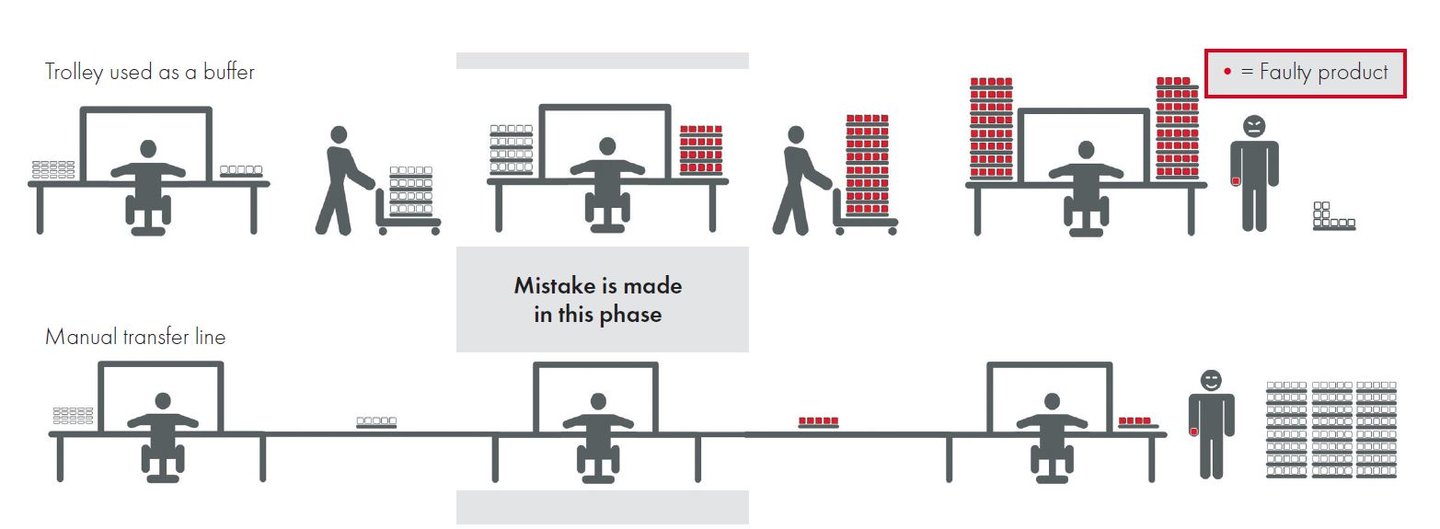

OnePiece Flow Onepiece flow, sometimes called continuous flow or singlepiece flow, is a production method used instead of traditional mass production In mass production, materials move through the manufacturing process in batches which can be highly inefficient In onepiece flow, a product is completed before the next one is started Another one is that, with the batch method, you may be able to continue processing even if a problem occurs because of the extra inventory You may not even notice the problem On the other hand, the OnePiece Flow method allows you to find and fix any issues as soon as they occur because there is no extra inventory Onepiece flow means that parts are moved through operations from steptostep with no work in process in between;

Benefits Of One Piece Flow And How It Is Implemented Latest Quality

Lean Manufacturing One Piece Flow Vs Batch Flow

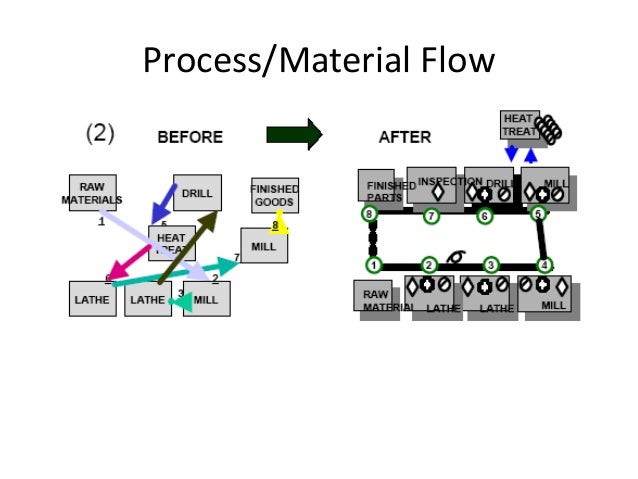

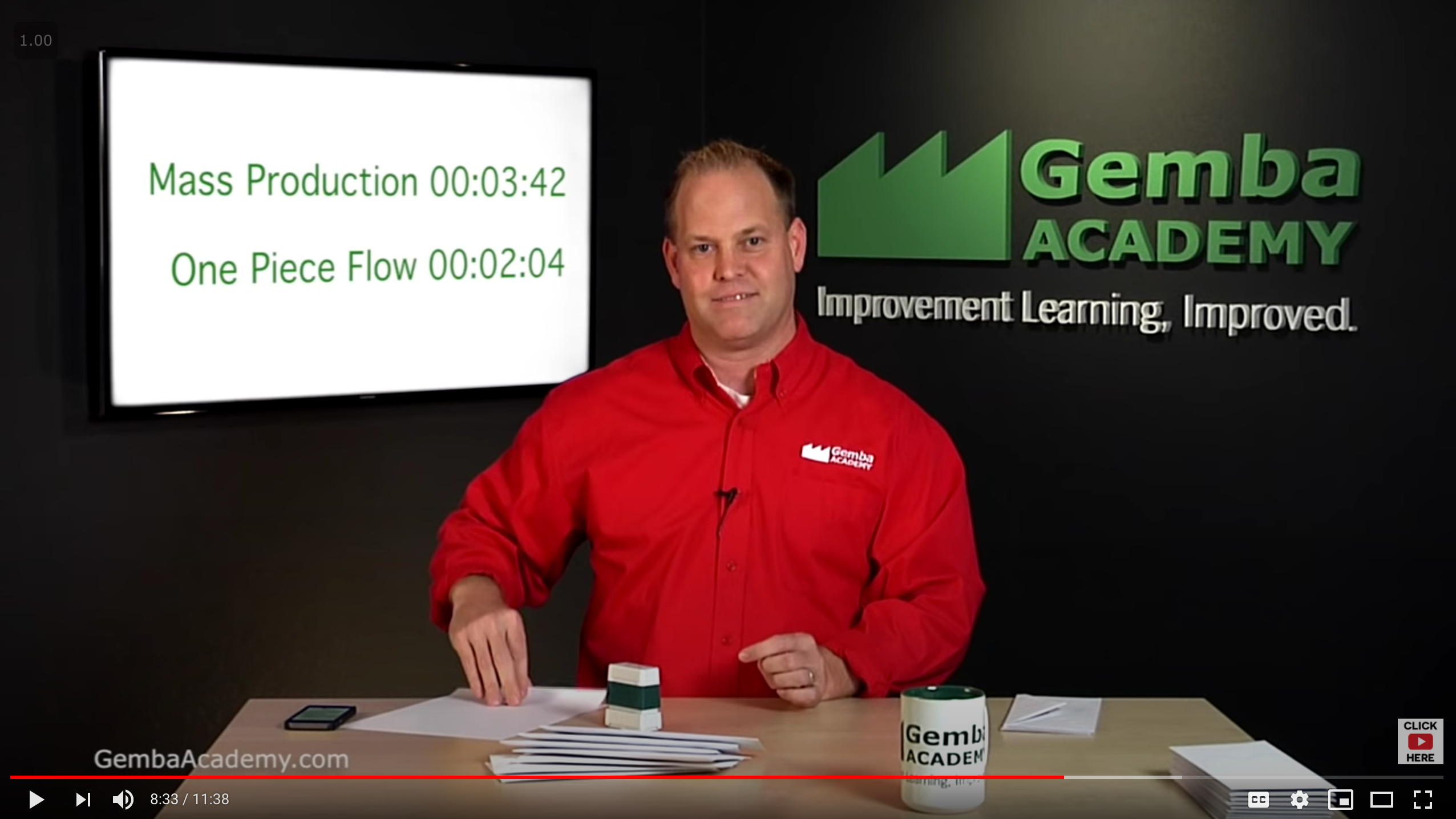

This exercise will show which process is faster The faster process yields the benefits we discussed (recall benefits) Batch v Lean 1 piece flow training 1 Lean 1Pc Flow vs Batch & Que Production Developed by Julian Kalac, PEng Lean Six Sigma Master Black Belt 1 2 5 S IN BVENT AREABEFORE 3 3 BEFORE 5 S 4 4 BVENT AFTER 5S 5 5 BVENT AFTER 5 S 6 6 Process/Material Flow 7 8 8 In the simplest of terms, onepiece flow means that parts are moved through operations from steptostep with no WIP in between either one piece at a time or a small batch at a time This system works best in combination with a cellular layout in which all necessary equipment is located within a cell in the sequence in which it is used

One Piece Flow And Labor Density The Mail Example

One Piece Flow Youtube

Arbulu et al (02) discuss batch sizes and their influence on lead times and production flows in AEC supply chains They use simulation to show that large batches result in long lead times, whereas a onepieceflow, or at least a small batch size, allows for a smooth flow of work with more frequent handoffs and consequently smaller lead timesOne Piece Flow vs Batch Flow This video will explain to you the benefits of onepieceflow production compared to mass production ONLY FOR LEANVLOG COMMUNITY MEMBER Kanban Explained by a Real Life Example Understand the Kanban byDonde quiera que exista una empresa " de valor agregado ", hay un proceso de producción El Ingeniero Industrial se centra en " cómo " se hace un producto o " cómo " se brinda un servicio

Batch Vs One Piece Flow Manufacturing Treston

2

Batching of products because process steps are not connected or because setup times are long), having more floor space than required MOVEMENT Material and tools not stored at point of use, excess walking (eg to check, adjust or refill stations on the machine), lack of standards (eg looking for items because they do not have a With single piece flow, the idea is to make a piece only when the customer asks for one Use Single piece flow obviously works well with a justintime methodology This is in contrast with batch processing Many organizations believe batch processing is the most efficient way to produce It flies in the face of common sense, but the truth is — batch processing usuallyOnePieceFlow is a methodology that can be utilized to ensure that all of the aforementioned wastes are eliminated This process involves visualizing all the unit operations of a process and identifying based on the definitions, what wastes should be eliminated per unit area Unit operations could include raw materials, process one, process

Get Started With Lean Manufacturing Tools Smartsheet

Process Flow Diagram An Overview Sciencedirect Topics

Onepiece flow describes the sequence of product or of transactional activities through a process one unit at a time In contrast, batch processing creates a large number of products or Lean Simulations Batch vs One Piece Flow with SetupManufacturing Approvesparse 006 PDF Download Applied Groundwater Modeling Simulation of Flow and Advective Transport PDF Avimayu 007 Read Book Applied Groundwater Modeling Second Edition Simulation of Flow and Advective Transport Wilkey 006But One Piece Flow Vs what if talking is easy, but writing is difficult Then the service will come to the rescue Then the service will come to the rescue Portal where everyone can get english paper writing help will help in moments when you can not One Piece Flow Vs do without the text to get a job or a degree at the University

One Piece Flow Japanese Gemba Kaizen Web

Lean One Piece Flow Is Simple Voiceover Version Youtube

Struggling to demonstrate the benefits of SPF, this short video should help clarify thatFor more on these lessons go to wwwquantumleancahttps//quantumleancaOnePiece Flow vs Batching A Guide to Understanding How Continuous Flow Maximizes Productivity and Customer Value provides concrete arguments as to why batching, while sometimes necessary, is never the most efficient solution for most processes It explains why flow, especially onepiece flow or continuous flow, should always be your ultimate One Piece Flow (SinglePiece Flow) refers to the concept of moving one workpiece at a time between operations within a workcell Takt time is the average time between the start of production of one unit and the start of production of the next unit, when these production starts are set to match the rate of customer demand

Case Study Lean In Healthcare Seeing With New Eyes Pdf Free Download

The 8 Best Order Picking Methods Including Batch Picking

Either one piece at a time or a small batch at a time Once work on a product begins it never stops moving until it is a finished product As opposed to onepiece flow, batchandqueue processing is the action of producing more than one piece of an item andPipeline Pigging Pig Types, Pig Launcher, and Receiver The process of driving the pig through a pipeline by the fluid is called a pipeline pigging operation The term pig was originally referred to GoDevil scrapers which were driven through the pipeline by the flowing fluid trailing springloaded rakes for removing the wax off the internal

Pdf The Effectiveness And Impacts Of One Piece Flow Manufacturing Technique Into Manufacturing Industries The Effectiveness And Impacts Of One Piece Flow Manufacturing Technique Into Manufacturing Industries

How One Piece Flow Can Reduce Your Operations Time By 96 Business 2 Community

Which Is More Productive Batch Working Or One Piece Flow Flowmotion

One Piece Flow Vs Batching A Guide To Understanding How Continuous F

How One Piece Flow Can Reduce Your Operations Time By 96 Process Street Checklist Workflow And Sop Software

One Piece Flow Single Piece Flow Example

Pdf Optimal Batch Quantity Models For A Lean Production System With In Cycle Rework And Scrap

Which Is More Productive Batch Working Or One Piece Flow Flowmotion

Concrete Plant Wikipedia

Static S123 Cdn Static Com

One Piece Flow Cell Design For Transforming The Production Process Author Sekine Kenichi March 05 Sekine Kenichi Amazon Com Books

Continuous

One Piece Flow Single Piece Flow Example

The Best Single Piece Flow V S Batch Example Lean Manufacturing Youtube

Standardized Work Swip And One Piece Flow The Core Mathematics Of Lean

Communication Clipart Lean Manufacturing One Piece Png Download Pinclipart

Roche Ihccompwhitepaperitaly For Client Review 4 Flip Ebook Pages 1 11 Anyflip Anyflip

35 Lean Manufacturing Tools The Ultimate List

Pdf Impact Of One Piece Flow On Economic Data Quality And Shop Floor Data Collection Gordon Peters Academia Edu

Batch V Lean 1 Piece Flow Training

2

A Large Scale Experimental Comparison Of Batch And Continuous Technologies In Pharmaceutical Tablet Manufacturing Using Ethenzamide Sciencedirect

Batch Vs One Piece Flow Manufacturing

Batch V Lean 1 Piece Flow Training

Single Piece Flow An Example

One Piece Flow Cell Design For Transforming The Production Process Sekine Kenichi Amazon Com Books

Batch Vs One Piece Flow Manufacturing Treston

Real Time Vs Batch Processing Vs Stream Processing Bmc Software Blogs

One Piece Flow Versus Batch Production Lean Manufacturing Youtube

What Is A Data Pipeline Bmc Software Blogs

Batch Production Vs One Piece Flow Youtube

10 Lean Manufacturing Ideas For Machine Shops Modern Machine Shop

Spring Batch Reference Documentation

One Piece Flow Iso Consultant In Kuwait

Batch Processing Versus One Piece Flow Download Scientific Diagram

Ask Art Why Do I Need To Switch From Batch To Flow

Lean Thinking And Methods Cellular Manufacturing Us Epa

Value Stream Mapping Vsm Mudamasters

Ask Art How One Piece Flow Supports Quality

Achieving One Piece Flow

Batch V Lean 1 Piece Flow Training

Achieving One Piece Flow

One Piece Flow Manufacturing Creative Safety Supply

One Piece Flow Iso Consultant In Kuwait

One Piece Flow Versus Batch Production Lean Manufacturing On Make A Gif

Glossary Of Lean And Related Terms 21 Ci Conference

Comparison The Batch Production And One Piece Flow Activity Download Table

One Piece Flow Vs Batching A Guide To Understanding How Continuous F

Spring Batch Reference Documentation

2

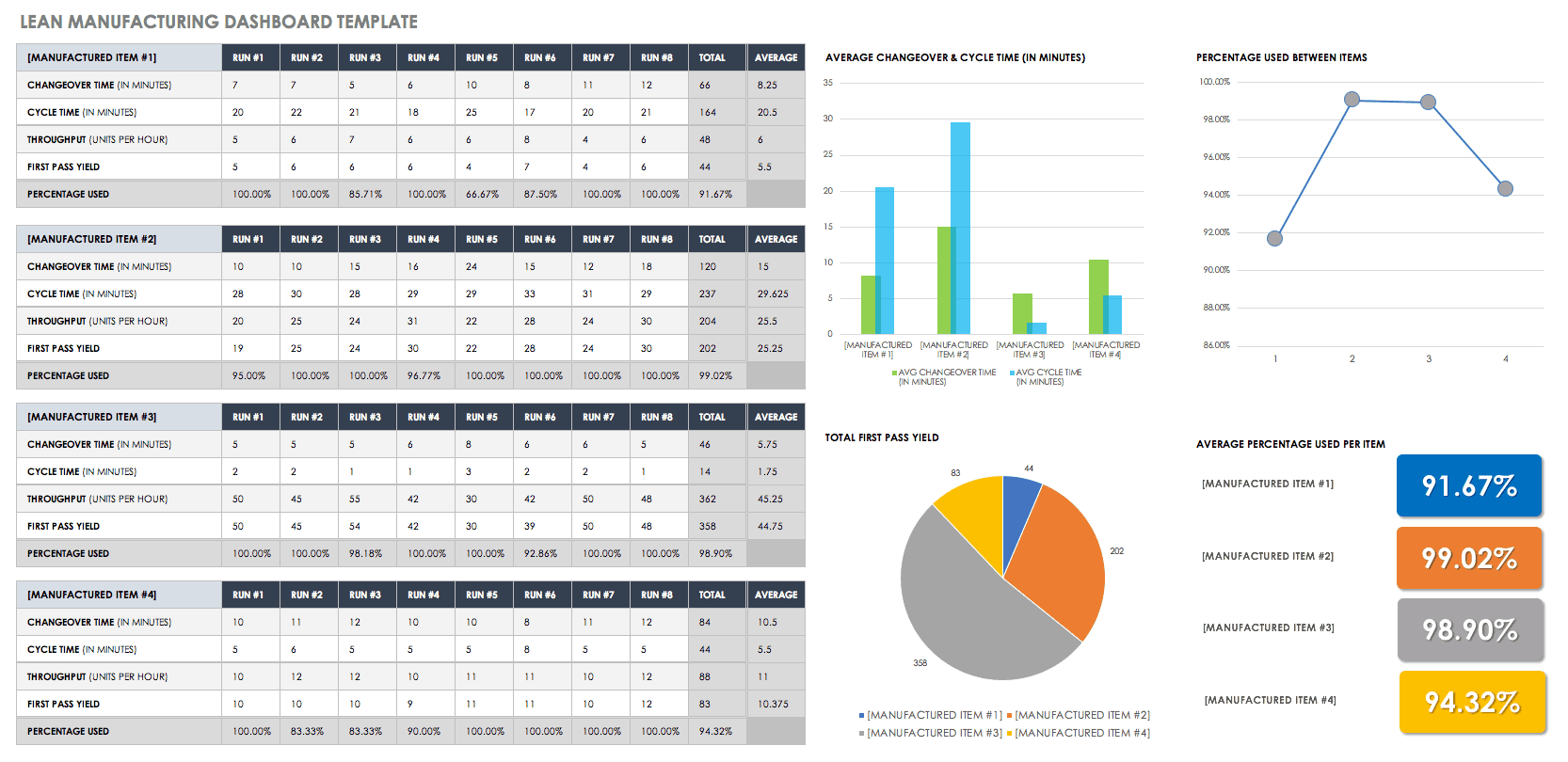

Get Started With Lean Manufacturing Tools Smartsheet

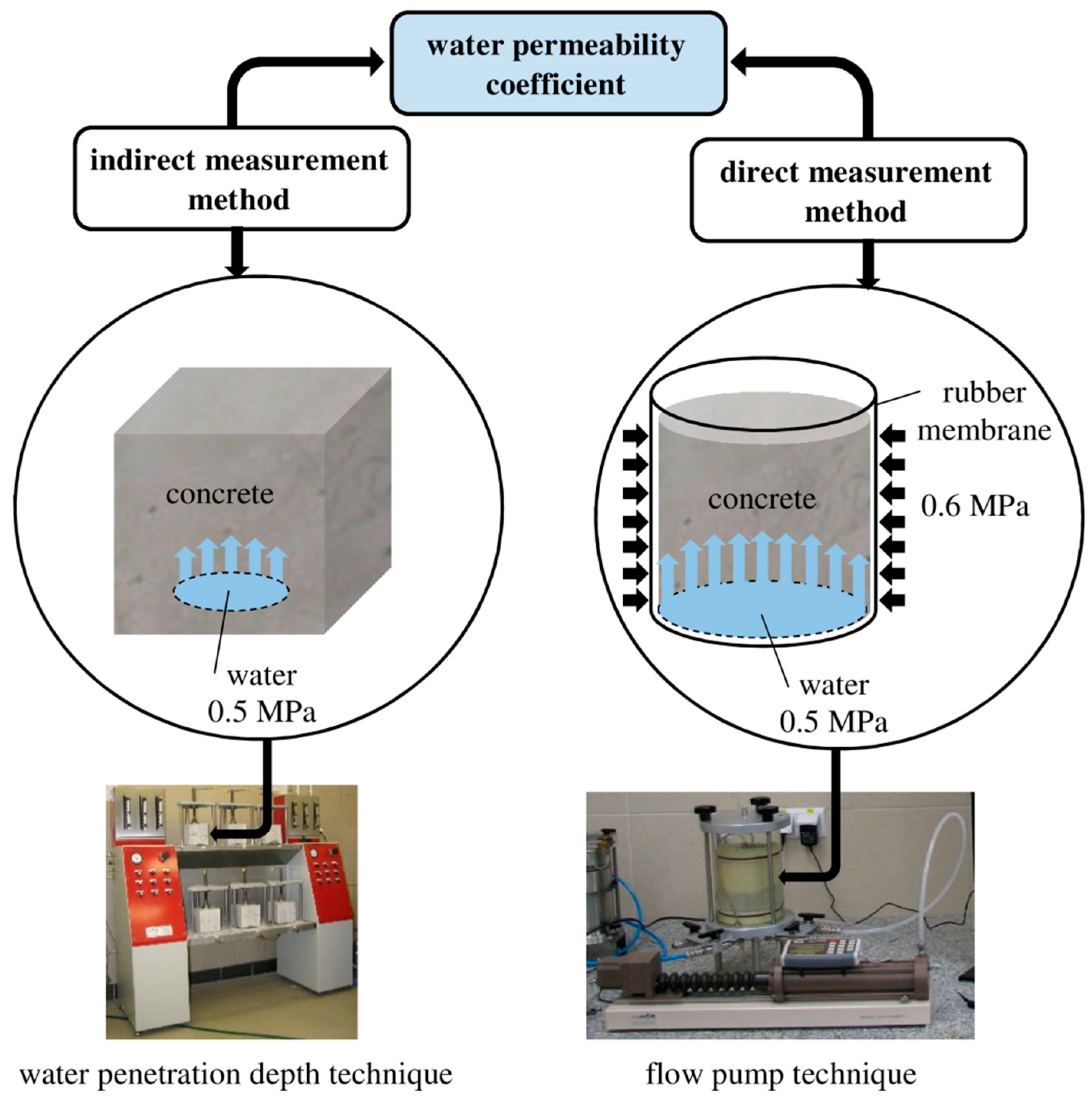

Materials Free Full Text An Experimental Assessment Of The Water Permeability Of Concrete With A Superplasticizer And Admixtures Html

Static S123 Cdn Static Com

Batch Vs One Piece Flow Manufacturing Treston

One Piece Flow Vs Batching A Guide To Understanding How Continuous F

What Is One Piece Flow In The Production Process Breakout

1

Pdf The Effectiveness And Impacts Of One Piece Flow Manufacturing Technique Into Manufacturing Industries The Effectiveness And Impacts Of One Piece Flow Manufacturing Technique Into Manufacturing Industries

Discipline Strategy Book By Timothy Coomer Phd Official Publisher Page Simon Schuster

En Batch Vs One Piece Flow Airport Youtube

Batch V Lean 1 Piece Flow Training

The Differences Between Batch Processing And Continuous Flow Processing General Kinematics

One Piece Flow

Pdf Impact Of One Piece Flow On Economic Data Quality And Shop Floor Data Collection Gordon Peters Academia Edu

How One Piece Flow Can Reduce Your Operations Time By 96 Process Street Checklist Workflow And Sop Software

Lean Simulations Batch Vs One Piece Flow With Setup Manufacturing Video Dailymotion

One Piece Flow Iso Consultant In Kuwait

Lean Manufacturing One Piece Flow Vs Batch Flow

Batch V Lean 1 Piece Flow Training

What Is One Piece Flow In The Production Process Breakout

10 Benefits Of One Piece Flow Gemba Academy

One Piece Flow

How One Piece Flow Can Reduce Your Operations Time By 96 Process Street Checklist Workflow And Sop Software

Batch Vs One Piece Flow With Setup Manufacturing Free Simulation Youtube

Pdf The Effectiveness And Impacts Of One Piece Flow Manufacturing Technique Into Manufacturing Industries The Effectiveness And Impacts Of One Piece Flow Manufacturing Technique Into Manufacturing Industries

What Is One Piece Flow In The Production Process Breakout

What Is One Piece Flow In The Production Process Breakout

One Piece Flow Vs Batch Work Getting Our Heads Around Which Is Better Accuturn

0 件のコメント:

コメントを投稿